Pure water or with flavor? Standard round bottle or special designed shape bottle? All of them can be packed by our mono-block machines.

What is the water bottling project? From A to Z, water will go through water treatment system, automatic water bottling machine, bottle labeling and wrapping system, etc.

In this production line, the automatic water bottling system is the most important.

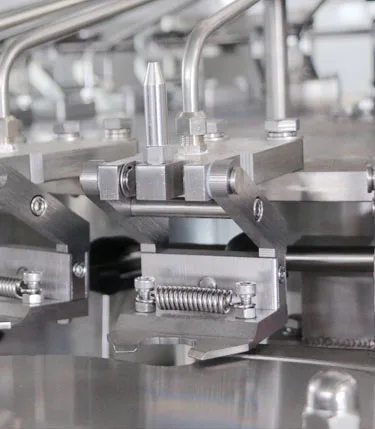

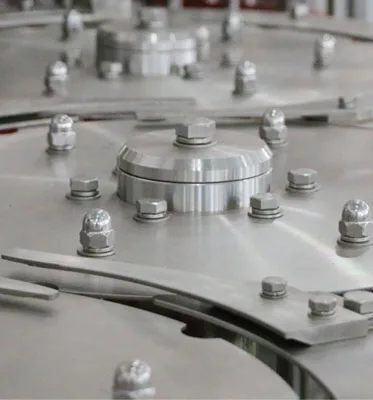

Our new generation SYD series water filling machine has broken the rules, which risen the capacity at least 30% than competitors. New filling system with vacuum system makes the water filling speed 30%-40% faster than before. Full new capping system makes the cap seal steady and not easy broken.